PRODUCTION PROCESS

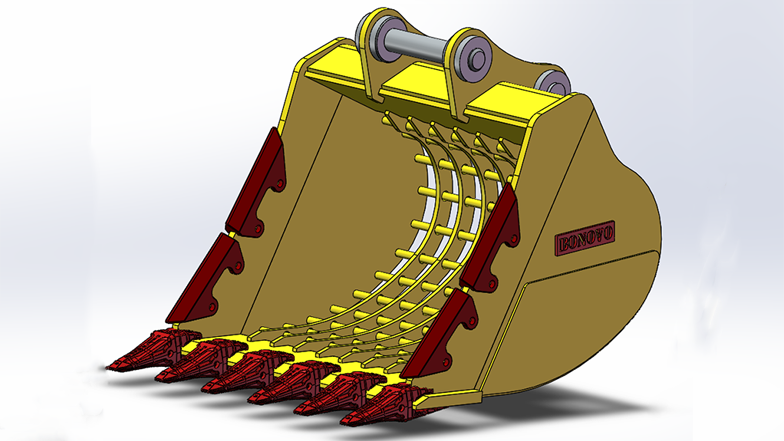

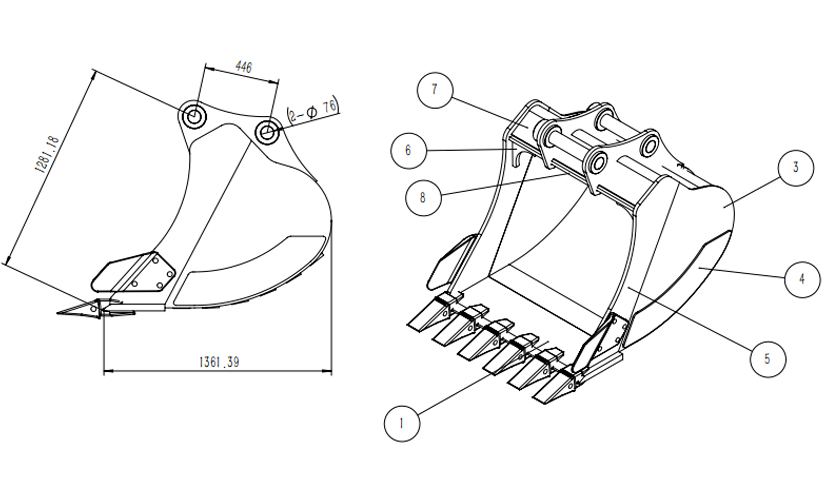

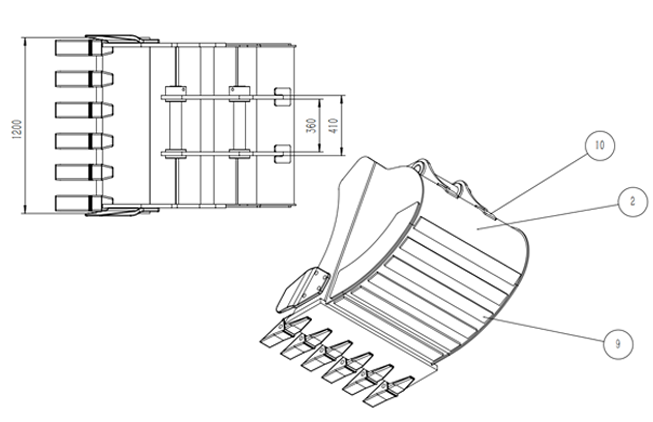

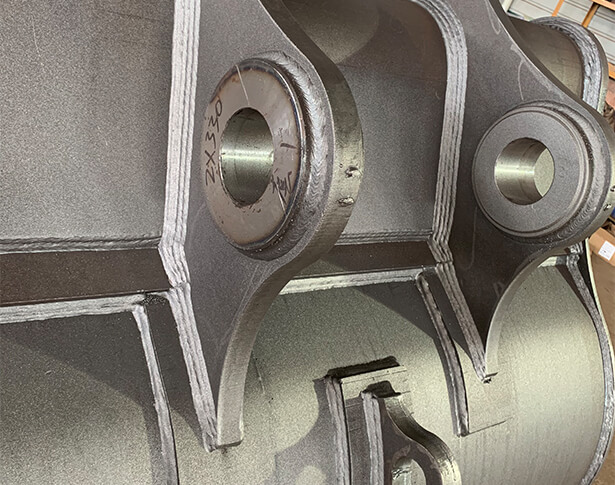

We understand that the perfect combination of high-quality cast steel and advanced heat treatment technology is the key factor for the success of the Bonovo brand. You can rely on the quality of our landing gear components, backed by our extended warranties. The 70,000sqf warehouse is ready to meet your urgent delivery, and the strong R&D and the most professional sales team are sure to meet any of your customized requirements in a timely manner.

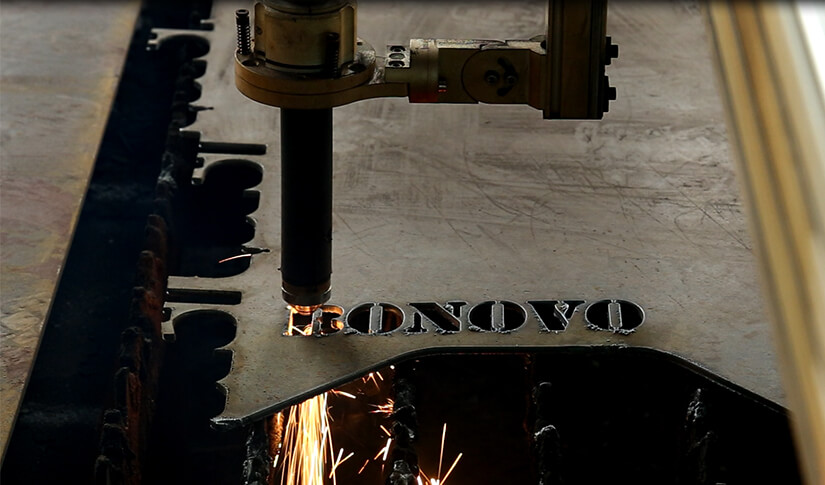

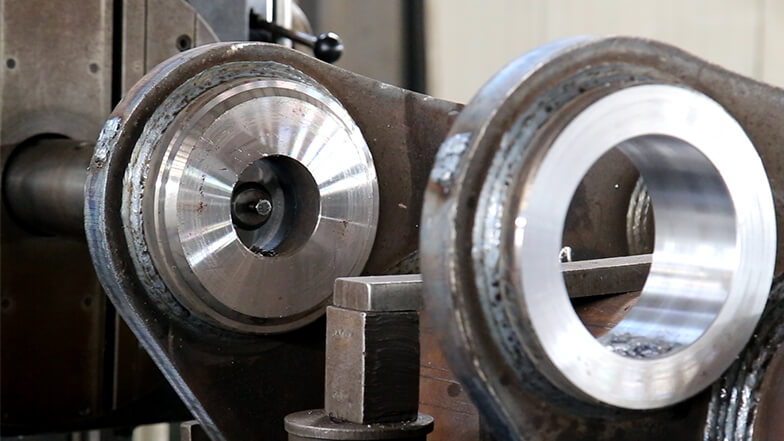

Production Process

FAQ

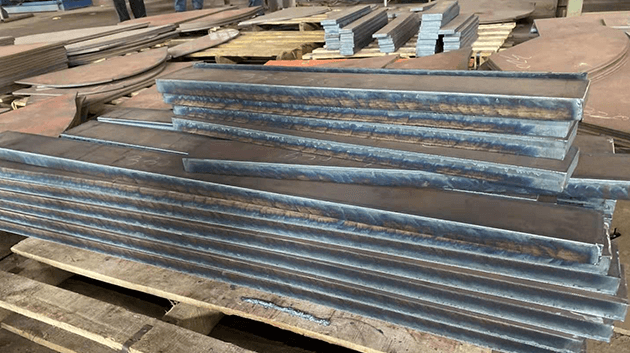

Many type of steel plates are available, Q345, NM400, Hardox, etc

Turnbuskle, positioning tooling, steel ruler

Remove the surface oxide layer, remove welding flow, increase paint adhesion.